Introduction

When it comes to the world of manufacturing, there are various types of manufacturing processes that play a crucial role in shaping the products we use every day. Understanding the types of manufacturing is essential for companies like SSOURCING INC. to make informed decisions about production methods and strategies. From traditional methods to advanced technologies, there is a diverse manufacturing landscape that offers unique opportunities and challenges.

Understanding the Types of Manufacturing

The types of manufacturing encompass a wide range of processes, including craftsman manufacturing, assembly line production, batch manufacturing, 3D printing, robotics in manufacturing, custom fabrication, and more. Each method brings its own set of advantages and limitations, making it vital for companies like SSOURCING INC. to carefully consider which approach best aligns with their production goals and resources.

Importance of Different Manufacturing Methods

The importance of different manufacturing methods cannot be overstated. Whether it's optimizing efficiency, reducing costs, or enhancing product quality and customization capabilities, choosing the right method can significantly impact a company's success in the market. SSOURCING INC., as an industry leader in innovative products, understands the critical role that different manufacturing methods play in achieving business objectives.

A Look into the Diverse Manufacturing Landscape

Taking a closer look at the diverse manufacturing landscape reveals an evolving industry that continues to embrace new technologies and sustainable practices while navigating global trends such as offshoring vs reshoring and nearshoring strategies. As SSOURCING INC. continues to expand its global footprint, understanding this diverse landscape becomes even more crucial for strategic decision-making.

Traditional Manufacturing Methods

When it comes to the types of manufacturing, traditional methods have played a significant role in shaping the industry. Craftsman manufacturing, for example, is a method that involves skilled artisans creating products by hand using traditional tools and techniques. This approach emphasizes attention to detail and craftsmanship, making it ideal for producing high-quality, custom-made goods that appeal to niche markets. SSOURCING INC. recognizes the value of craftsman manufacturing in preserving traditional craftsmanship and meeting the demand for artisanal products.

Craftsman Manufacturing

Craftsman manufacturing is characterized by meticulous attention to detail and a focus on quality over quantity. Skilled artisans at SSOURCING INC. employ time-honored techniques to create unique, handcrafted products that showcase exceptional artistry and craftsmanship. This method allows for customization and personalization, catering to discerning customers who appreciate bespoke items tailored to their specific preferences.

Assembly Line Production

In contrast to craftsman manufacturing, assembly line production involves a systematic approach to mass-producing standardized goods at a rapid pace. This method relies on efficient processes and specialized machinery to streamline production and maximize output. SSOURCING INC. leverages assembly line production for large-scale manufacturing projects, ensuring cost-effective production of high-volume goods without compromising quality.

Batch Manufacturing

Batch manufacturing strikes a balance between craftsman manufacturing and assembly line production by producing goods in limited quantities with some degree of customization or variation within each batch. SSOURCING INC. embraces batch manufacturing as it allows for flexibility in meeting diverse customer demands while maintaining efficient production processes tailored to specific batch sizes.

Advanced Manufacturing Technologies

As we delve into the advanced manufacturing technologies, it's crucial to understand the impact of 3D printing, also known as additive manufacturing. This innovative method allows SSOURCING INC. to create complex designs and prototypes with precision and speed. With 3D printing, the traditional limitations of manufacturing are being reshaped, offering endless possibilities for customization and rapid production.

3D Printing

3D printing is revolutionizing the manufacturing landscape by enabling SSOURCING INC. to produce intricate components with minimal waste and maximum efficiency. This technology utilizes a layer-by-layer approach to build objects from digital models, allowing for on-demand production and reduced lead times. With 3D printing, our company can explore new design concepts and iterate rapidly without the constraints of traditional manufacturing processes.

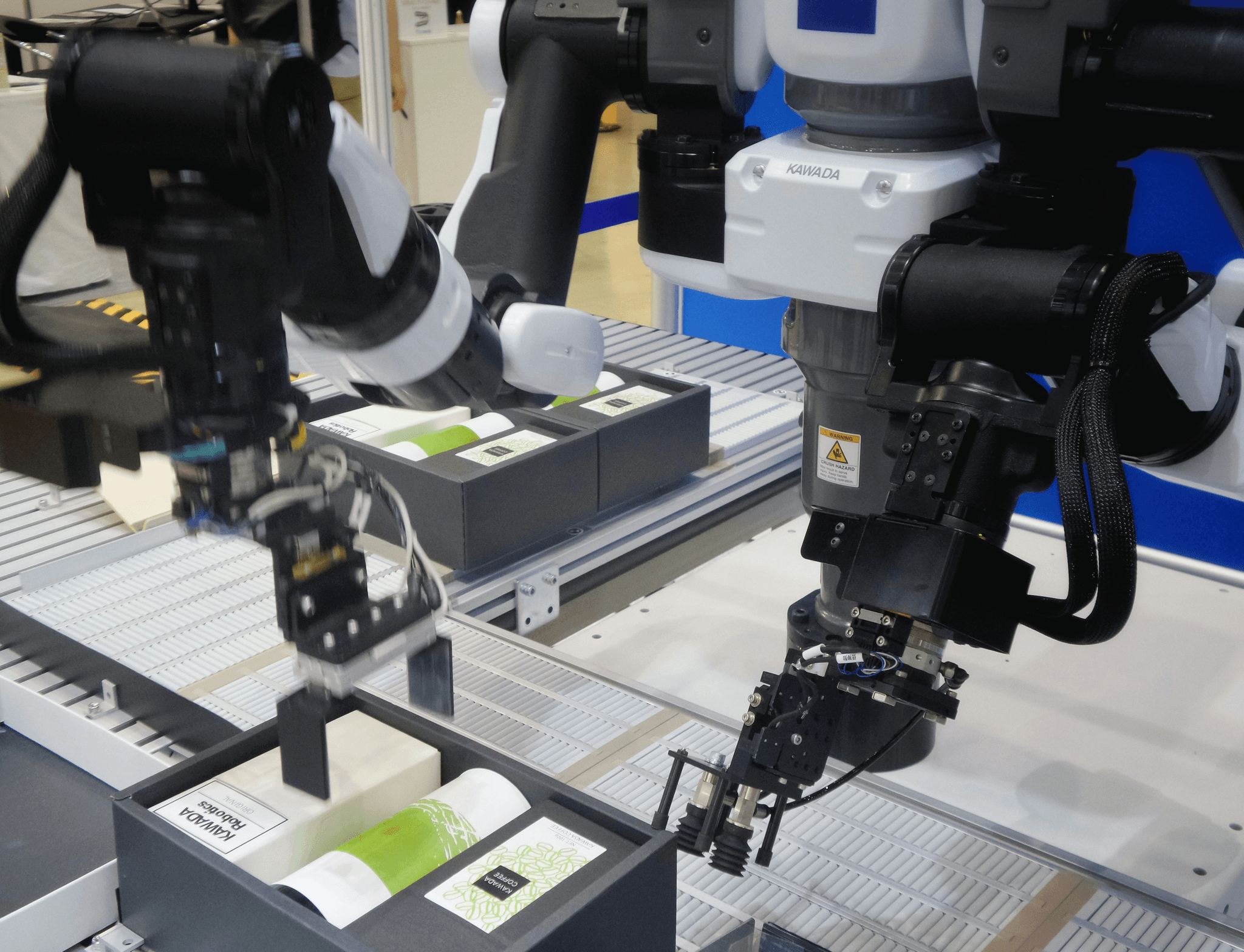

Robotics in Manufacturing

The integration of robotics in manufacturing has significantly enhanced SSOURCING INC.'s operational capabilities by automating repetitive tasks and increasing productivity. By leveraging robotic systems, our company can streamline assembly processes, improve quality control, and optimize resource utilization. With advancements in artificial intelligence and machine learning, robotics is poised to play an even more pivotal role in driving innovation within the manufacturing industry.

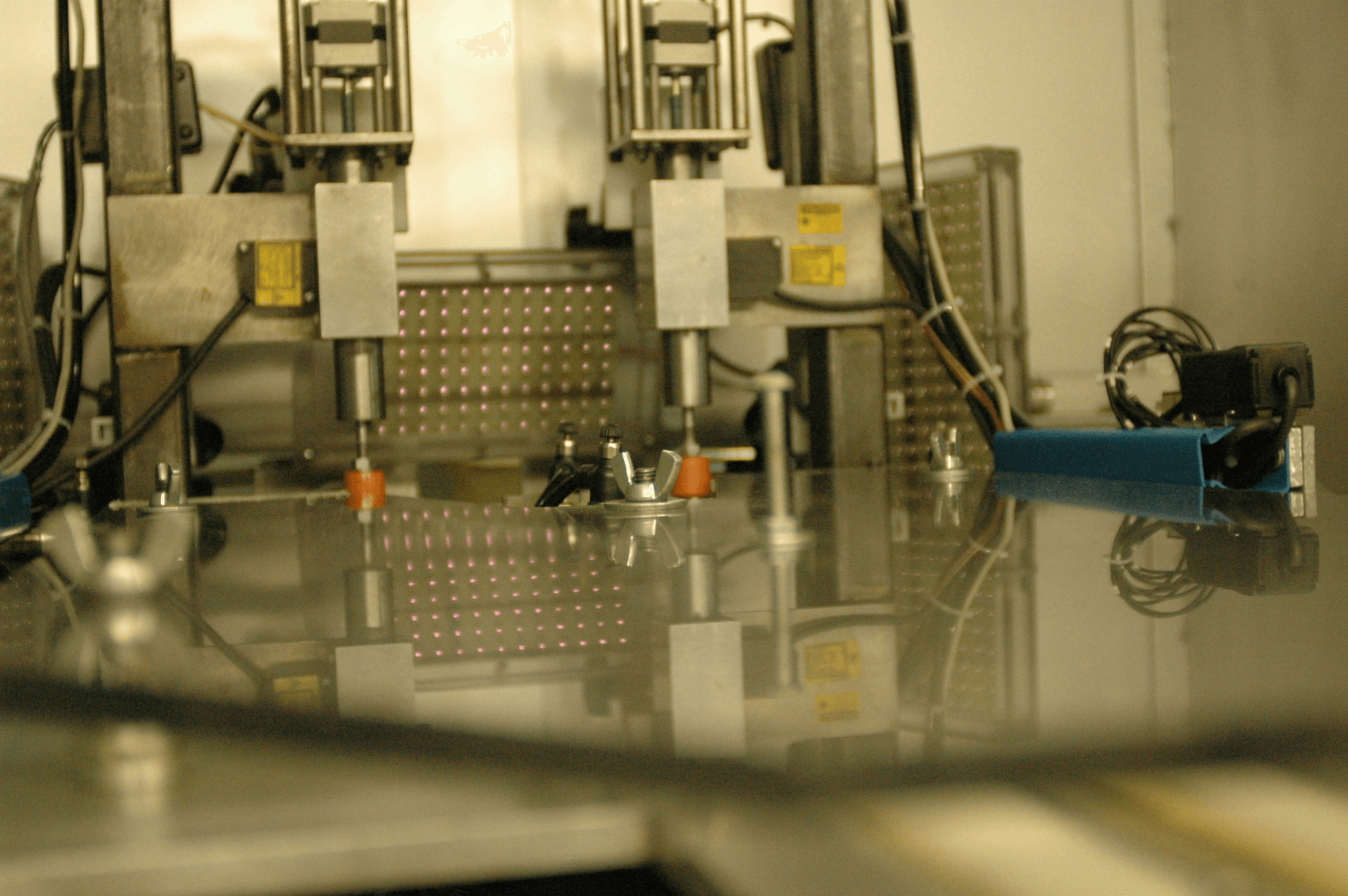

Smart Manufacturing

Smart manufacturing encompasses the use of interconnected systems and data-driven insights to optimize production processes at SSOURCING INC. Through the implementation of IoT devices, real-time monitoring, and predictive analytics, our company can achieve greater visibility into operations while minimizing downtime and enhancing overall efficiency. Embracing smart manufacturing technologies allows us to adapt swiftly to changing market demands while maintaining a competitive edge in the industry.

By incorporating advanced manufacturing technologies such as 3D printing, robotics, and smart manufacturing solutions into our operations at SSOURCING INC., we are poised to stay ahead of the curve in a rapidly evolving industry landscape.

Specialized Manufacturing Processes

When it comes to specialized manufacturing processes, SSOURCING INC. understands the importance of custom fabrication, which involves creating unique products tailored to specific client needs. This method allows for personalized solutions and high-quality craftsmanship, ensuring client satisfaction. With our expertise in custom fabrication, we can deliver exceptional results that meet and exceed expectations.

Custom Fabrication

Custom fabrication is a key aspect of SSOURCING INC.'s manufacturing approach, as it enables us to produce one-of-a-kind products that cater to individual client requirements. By utilizing advanced techniques and cutting-edge technology, we can create bespoke items with precision and attention to detail. Our dedication to custom fabrication sets us apart in the competitive manufacturing landscape, showcasing our commitment to delivering tailored solutions for our clients.

Lean Manufacturing

SSOURCING INC. embraces lean manufacturing principles to streamline production processes and eliminate waste, ultimately improving efficiency and reducing costs for our clients. By focusing on continuous improvement and minimizing non-value-added activities, we maximize value for our customers while maintaining high standards of quality in every aspect of production.

Just-In-Time Manufacturing

Just-in-time (JIT) manufacturing is another specialized process that SSOURCING INC. employs to optimize inventory management and reduce lead times. This approach allows us to fulfill orders promptly without excess stockpiling or overproduction, leading to cost savings and improved responsiveness to market demands.

Incorporating these specialized manufacturing processes into our operations at SSOURCING INC., we ensure that our clients receive tailored solutions with maximum efficiency and minimal waste throughout the production cycle. Our commitment to excellence drives us to continually refine our methods and embrace innovative approaches in order to deliver superior results for every project we undertake.

Sustainable Manufacturing Practices

Sustainable manufacturing practices have become increasingly important in today's industrial landscape. As companies aim to reduce their environmental footprint, eco-friendly manufacturing has gained traction. SSOURCING INC. recognizes the significance of implementing sustainable manufacturing practices to meet the demands of environmentally conscious consumers.

Eco-Friendly Manufacturing

Eco-friendly manufacturing involves using processes that minimize waste and reduce environmental impact. By utilizing renewable resources and reducing energy consumption, companies can lower their carbon footprint and contribute to a healthier planet. At SSOURCING INC., we are committed to promoting eco-friendly manufacturing methods that align with our sustainability goals and resonate with our environmentally conscious clients.

Green Manufacturing

Green manufacturing focuses on integrating environmentally friendly practices into the production process, from sourcing raw materials to product distribution. This approach emphasizes resource efficiency, waste reduction, and recycling initiatives. SSOURCING INC.'s dedication to green manufacturing is evident in our efforts to implement sustainable practices across our supply chain, ensuring that we uphold high environmental standards in all aspects of production.

Renewable Energy in Manufacturing

Incorporating renewable energy sources such as solar or wind power into manufacturing processes is a key component of sustainable production methods. By harnessing clean energy alternatives, companies can significantly reduce their reliance on non-renewable resources and decrease greenhouse gas emissions. SSOURCING INC.'s commitment to utilizing renewable energy in manufacturing underscores our dedication to minimizing environmental impact while meeting the evolving needs of the market.

Global Manufacturing Trends

In today’s globalized economy, manufacturing trends are constantly evolving to meet the demands of the market. With the rise of automation and digital technologies, manufacturers are faced with the decision of offshoring versus reshoring their production processes. This decision involves weighing the cost benefits of outsourcing production overseas against the advantages of bringing it back to domestic shores. SSOURCING INC. understands the importance of making informed decisions in this regard and can provide valuable insights into these global manufacturing trends.

Offshoring vs Reshoring

Offshoring has been a popular choice for many companies looking to reduce labor and production costs by relocating their manufacturing operations to countries with lower labor costs. However, recent trends have seen a shift towards reshoring, as companies recognize the benefits of localizing their production processes to improve quality control and reduce supply chain risks. SSOURCING INC. can help navigate through these complex decisions by providing comprehensive analysis and strategic recommendations tailored to individual business needs.

Nearshoring Strategies

Nearshoring strategies have also gained traction as an alternative to both offshoring and reshoring. This approach involves relocating manufacturing operations to nearby countries with lower labor costs while maintaining geographical proximity for logistical advantages. By leveraging nearshoring strategies, companies can benefit from cost savings while minimizing some of the risks associated with offshore production. SSOURCING INC.'s expertise in global manufacturing trends can assist in identifying suitable nearshoring opportunities for businesses seeking to optimize their production processes.

Multi-Location Manufacturing

The concept of multi-location manufacturing has become increasingly prevalent as companies seek to diversify their production footprint across different regions or countries. This strategy offers resilience against disruptions in supply chains and provides access to diverse talent pools and markets. SSOURCING INC.'s comprehensive understanding of multi-location manufacturing enables businesses to capitalize on this trend by strategically expanding their operations across various locations while mitigating potential risks associated with a single-point dependency.

By staying abreast of global manufacturing trends such as offshoring, reshoring, nearshoring strategies, and multi-location manufacturing, SSOURCING INC. is well-equipped to guide businesses towards making informed decisions that align with their long-term growth objectives in today’s dynamic marketplace.

Conclusion

In conclusion, exploring modern manufacturing solutions is crucial for the success of any business in today's competitive market. With the rapid advancements in technology, it is essential for companies to stay updated with the latest types of manufacturing methods to stay ahead of the curve. SSOURCING INC. understands the importance of adapting to the changing manufacturing landscape and is committed to enhancing operational efficiency with strategic manufacturing choices.

Exploring Modern Manufacturing Solutions

As we delve into the world of modern manufacturing solutions, it becomes evident that embracing advanced technologies such as 3D printing, robotics, and smart manufacturing can revolutionize production processes. These innovative methods not only streamline operations but also pave the way for cost-effective and sustainable manufacturing practices, which are crucial for long-term success in today's market.

Adapting to the Changing Manufacturing Landscape

The changing manufacturing landscape requires companies to be agile and adaptable in their approach. With globalization and evolving consumer demands, it is essential for businesses to consider offshoring vs reshoring strategies, nearshoring options, and multi-location manufacturing facilities to optimize their supply chain and remain competitive in a dynamic market environment.

Enhancing Operational Efficiency with Strategic Manufacturing Choices

Enhancing operational efficiency through strategic manufacturing choices is paramount for sustainable growth and profitability. By implementing specialized processes such as custom fabrication, lean manufacturing, and just-in-time production methods, companies can optimize their resources while minimizing waste and maximizing productivity.

By embracing modern solutions, adapting to changes in the industry landscape, and making strategic choices in manufacturing processes, SSOURCING INC. aims to lead the way in innovative and sustainable production practices that drive success in today's competitive market environment.