Introduction

When looking to bring your product to market, finding the right manufacturer is crucial. Understanding your product manufacturing needs is the first step in this process. Whether you are seeking a product manufacturing company or suppliers in China, it's essential to have a clear understanding of your production requirements and quality standards.

Understanding Your Product Manufacturing Needs

To find a manufacturer for your product, start by identifying the specific requirements for its production. Consider factors such as materials, production volume, and any specialized processes needed. SSOURCING INC. can assist you in defining these needs and ensuring that they align with your overall business goals.

Researching Potential Manufacturers

Once you have a clear understanding of your product's manufacturing needs, the next step is to research potential manufacturers. This involves identifying supplier companies that align with your requirements and have a proven track record of delivering high-quality products.

Assessing Quality and Reliability

In evaluating potential manufacturers, it's crucial to assess their quality and reliability. This includes verifying compliance and certification, as well as evaluating past performance and client feedback to ensure that you are partnering with a reputable manufacturing supplier.

Negotiating Terms and Pricing

Negotiating terms and pricing with potential manufacturers is an important aspect of the process. Understanding cost structures, minimum order quantities (MOQ), lead times, payment terms, and contracts is essential for securing favorable terms that benefit both parties.

Finalizing the Manufacturing Partnership

Once terms have been negotiated, finalizing the manufacturing partnership involves signing agreements and contracts with the chosen manufacturer. It also entails establishing clear communication channels for ongoing collaboration and planning for continuous improvement.

Researching Potential Manufacturers

When looking for product manufacturers, it's crucial to identify top manufacturing companies that have a proven track record of delivering quality products. SSourcing Inc. can start by leveraging industry networks, attending trade shows, and utilizing online directories to compile a list of potential suppliers. By focusing on companies that specialize in your specific product niche, you can narrow down the options to those best suited for your needs.

Identifying Top Manufacturing Companies

To find a manufacturer for your product, it's essential to conduct thorough research and due diligence in order to identify reputable manufacturing companies. Look for suppliers with extensive experience in producing similar products and a strong reputation within the industry. SSourcing Inc. can also consider factors such as location, production capacity, and specialization to further narrow down the list of potential manufacturers.

Evaluating Manufacturing Capabilities

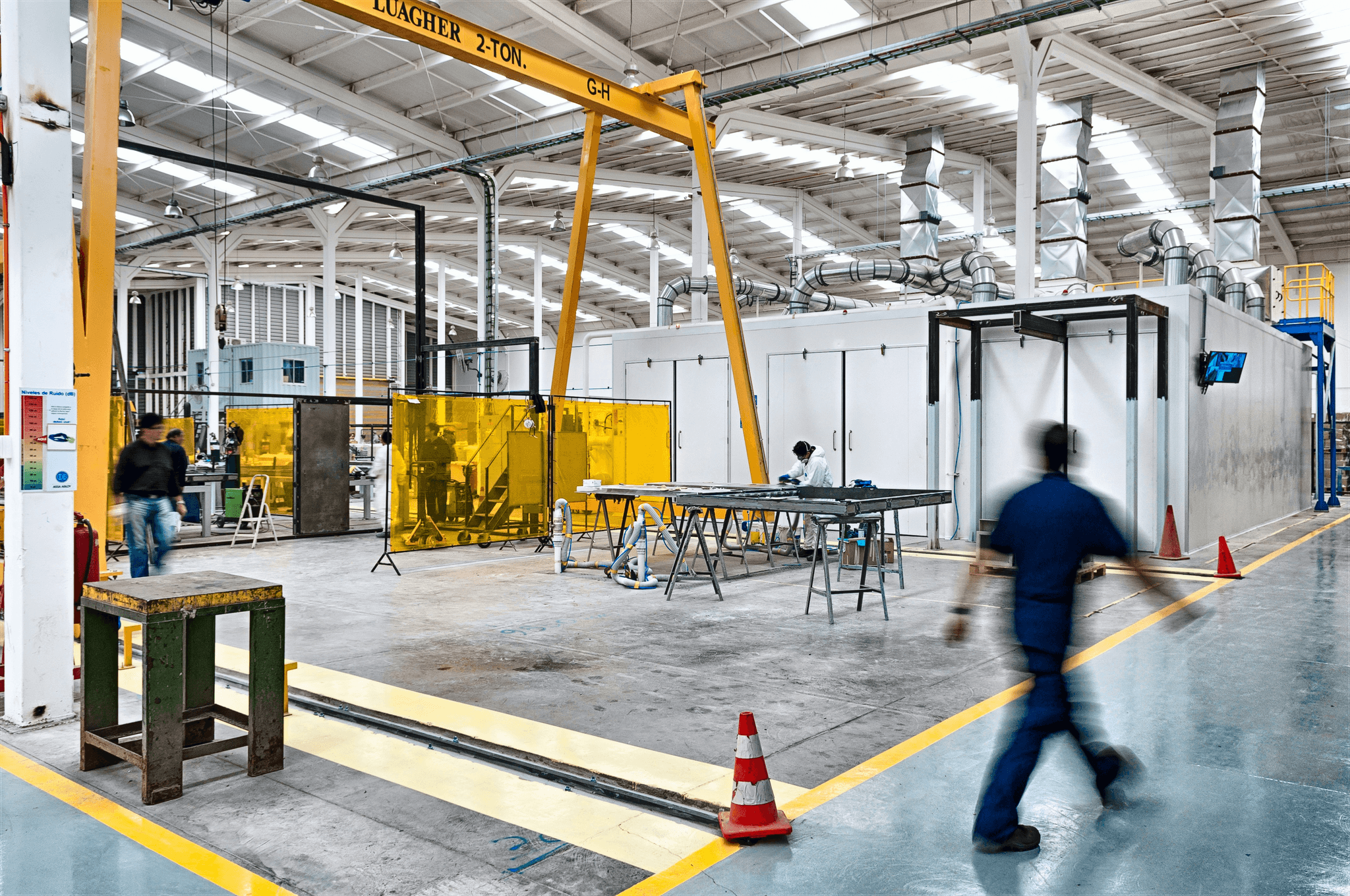

Once you've identified a list of potential manufacturing partners, it's important to evaluate their capabilities thoroughly. This involves assessing their production processes, technology infrastructure, and quality control measures. SSourcing Inc. should prioritize visiting manufacturing facilities or conducting virtual tours to gain firsthand insight into their operations and determine if they align with your product requirements.

Assessing Production Capacity

Finding a manufacturer that can meet your production needs is critical for a successful partnership. SSourcing Inc. should assess the production capacity of each potential supplier by considering factors such as lead times, scalability, and ability to accommodate future growth. Understanding their capacity ensures that they can fulfill your orders consistently and efficiently.

By visiting manufacturing facilities or conducting virtual tours as part of the evaluation process, you can gain valuable insights into their capabilities and operations.

Assessing Quality and Reliability

Ensuring Quality Standards

When looking for a product manufacturing company, it's crucial to ensure that they meet your quality standards. SSOURCING INC. recommends conducting thorough inspections of their facilities and requesting samples to evaluate the quality of their work. This step is essential in finding a manufacturer to make your product that aligns with your brand's quality expectations.

Verifying Compliance and Certification

In the process of finding a manufacturer in China or any other location, it's important to verify that the supplier company complies with industry regulations and holds relevant certifications. SSOURCING INC. suggests reviewing their compliance records and certifications to ensure that they adhere to international manufacturing standards, providing you with peace of mind regarding product quality.

Evaluating Past Performance and Client Feedback

Before finalizing a partnership with manufacturing suppliers, it's crucial to evaluate their past performance and client feedback. SSOURCING INC. advises reaching out to their previous clients for testimonials and conducting thorough research on their reputation in the industry. This step is vital in securing a trustworthy manufacturing partner for your business.

Remember that when researching potential manufacturers, assessing quality and reliability is a critical step in finding the right partner for your business needs. By ensuring quality standards, verifying compliance and certification, as well as evaluating past performance and client feedback, you can establish a long-term partnership with a reliable manufacturer that meets your product manufacturing needs effectively.

Negotiating Terms and Pricing

When looking for product manufacturers, it's essential to understand the cost structure involved in the manufacturing process. This includes not only the cost of materials and labor but also any additional expenses such as shipping and customs duties. By comprehensively understanding the cost structure, SSOURCING INC. can effectively negotiate pricing with potential manufacturing suppliers to ensure a mutually beneficial partnership.

Understanding Cost Structure

Negotiating MOQ (Minimum Order Quantity) and lead times is crucial when finding a manufacturer to make your product. SSOURCING INC. must assess its production needs and determine an MOQ that aligns with its budget and inventory requirements. Additionally, negotiating lead times is essential to ensure timely delivery of products to meet market demand without overstocking or understocking.

Negotiating MOQ and Lead Times

Discussing payment terms and contracts with potential manufacturing partners is a critical step in finalizing a manufacturing agreement. SSOURCING INC. should consider factors such as payment methods, payment schedules, and penalties for late payments when negotiating terms with product manufacturing companies. Furthermore, clear contracts outlining all terms and conditions are essential for establishing a transparent and trustworthy partnership.

Finalizing the Manufacturing Partnership

After thorough negotiations and discussions, it is crucial to solidify the partnership with the chosen product manufacturing company. Signing agreements and contracts with clear terms and conditions will ensure that both parties are aligned in their expectations and responsibilities. SSOURCING INC. understands the importance of having legally binding documents in place to protect both parties' interests.

Signing Agreements and Contracts

When finalizing the manufacturing partnership, it is essential to have legal agreements and contracts in place that outline the terms of the partnership, including pricing, production timelines, quality standards, and other important details. SSOURCING INC. ensures that all agreements are carefully reviewed by legal professionals to protect your interests as a client.

Establishing Clear Communication Channels

Clear communication channels between your company and the supplier company are crucial for a successful manufacturing partnership. SSOURCING INC. emphasizes the importance of establishing open lines of communication to ensure that any concerns or issues can be addressed promptly, ultimately leading to a more efficient manufacturing process.

Planning for Continuous Improvement and Collaboration

Once the partnership is finalized, it's important to plan for continuous improvement and collaboration with the chosen product manufacturer. SSOURCING INC. encourages ongoing dialogue with manufacturers to identify areas for improvement, streamline processes, and drive innovation in product development.

Remember that finding a manufacturer to make your product is just one step in building a successful business relationship; maintaining open communication channels, clear terms through signed agreements, and planning for continuous improvement are key factors in ensuring a successful long-term partnership with a reliable manufacturer like SSOURCING INC.

Conclusion

When looking to find a manufacturer for your product, it is crucial to follow a structured process to ensure the best partnership for your business. By understanding your product manufacturing needs and researching potential manufacturers, you can identify top manufacturing companies that align with your requirements. Assessing quality and reliability, negotiating terms and pricing, and finalizing the manufacturing partnership are essential steps in this process.

Securing a Trustworthy Manufacturing Partner

Securing a trustworthy manufacturing partner is vital for the success of your product. SSOURCING INC. understands the importance of finding a manufacturer that aligns with your values and goals, ensuring a reliable and long-term partnership.

Ensuring Quality Control and Compliance

Quality control and compliance are non-negotiable aspects when it comes to selecting a manufacturing partner. SSOURCING INC. prioritizes these factors in finding a manufacturer to make your product, ensuring that all products meet the highest standards.

Establishing a Long-Term Partnership with a Reliable Manufacturer

Establishing a long-term partnership with a reliable manufacturer is key to sustained success in product manufacturing. SSOURCING INC.'s approach focuses on continuous improvement and collaboration with manufacturing suppliers, fostering strong relationships for mutual growth.