Introduction

When starting a business, one of the crucial steps is finding the right manufacturing supplier for your product. Understanding your product needs is essential to identify the specific requirements and quality standards. Researching potential manufacturers near you or overseas can provide you with a wide range of options to consider. Evaluating manufacturer capabilities will help you determine if they are a good fit for your business needs.

Understanding Your Product Needs

To successfully find manufacturers for your product, it's important to have a clear understanding of what your business requires. Whether you have innovative business ideas or are looking for good starter businesses, defining your product needs will guide you in selecting the right manufacturing supplier that aligns with your goals and vision.

Researching Potential Manufacturers

Exploring manufacturers near me or abroad opens up opportunities to discover different business to business ideas and start a small business partnership. Researching potential manufacturers allows you to compare their capabilities, specialties, and customer feedback, helping you make an informed decision that suits your production volume and quality standards.

Evaluating Manufacturer Capabilities

Evaluating manufacturer capabilities involves checking their certifications, compliance, production facilities, and quality control measures. This step ensures that the manufacturing supplier can meet your specific requirements and provide consistent quality for successful production with SSOURCING INC.

Identifying Your Product Specifications

When looking to find manufacturers for your product, it's important to clearly define your product requirements. This includes outlining the specific features, materials, and design elements that are essential for your product. By detailing these requirements, you can effectively communicate your vision to potential manufacturing suppliers and ensure that they have the capabilities to meet your needs. At SSOURCING INC., we understand the significance of defining product specifications and can assist you in this crucial step of the manufacturing process.

Defining Your Product Requirements

Defining your product requirements involves identifying the essential components and functionalities that are necessary for your product. Whether it's the size, shape, or performance characteristics, clearly outlining these requirements will help you narrow down potential manufacturers who have the expertise and resources to bring your vision to life. At SSOURCING INC., we specialize in helping businesses like yours articulate their product needs and connect with suitable manufacturing partners.

Detailing Your Quality Standards

In addition to defining your product requirements, it's imperative to detail your quality standards when searching for manufacturing suppliers. This includes specifying any industry certifications or compliance standards that must be met, as well as outlining any specific quality control measures that are essential for maintaining consistency and reliability in production. Our team at SSOURCING INC. can guide you through this process and ensure that your quality standards are effectively communicated to potential manufacturers.

Outlining Your Production Volume

Another critical aspect of identifying your product specifications is outlining your production volume. Whether you require small-batch production or large-scale manufacturing, clearly communicating this volume requirement is crucial for finding manufacturers who can accommodate your production needs. By working with SSOURCING INC., we can help you assess different manufacturing options based on their capacity and capabilities to meet your production volume.

Remember that finding the right manufacturer for your product is a key step towards building a successful business venture. With careful consideration of these specifications and by partnering with SSOURCING INC., you can lay a solid foundation for successful production and business growth.

Researching Potential Manufacturers

When looking for manufacturing suppliers, it's important to consider both local and overseas options to find the best fit for your product needs. Local manufacturers offer the advantage of easier communication and potentially lower shipping costs, while overseas manufacturers may provide lower production costs and access to specialized technologies. By considering both options, SSOURCING INC. can help you weigh the pros and cons of each to make an informed decision.

Searching for Local and Overseas Options

To find manufacturers near you, start by reaching out to local business associations or trade shows in your industry. This can help you connect with nearby manufacturers who specialize in producing goods similar to yours. For overseas options, utilize online platforms such as Alibaba or ThomasNet to explore a wide range of international manufacturers. SSOURCING INC. can assist in researching and identifying potential partners based on your specific product requirements.

Analyzing Manufacturer Specializations

When evaluating potential manufacturing partners, consider their areas of expertise and whether they align with your product specifications. Look for manufacturers who have experience producing similar products or have specialized equipment that meets your unique needs. By analyzing manufacturer specializations, SSOURCING INC. can help you narrow down your options and find the best match for your business.

Reviewing Customer Feedback

Before making any decisions, take the time to review customer feedback and testimonials about potential manufacturers. This can provide valuable insight into their reputation, reliability, and overall satisfaction from past clients. By considering customer feedback as part of our thorough vetting process at SSOURCING INC., we ensure that you partner with reputable manufacturers who consistently deliver quality products.

Verifying Manufacturer Credentials

When looking for manufacturing suppliers, it's crucial to check their certifications and compliance with industry standards. This ensures that they meet the necessary requirements for producing your product. At SSOURCING INC., we understand the importance of working with manufacturers who adhere to quality and safety regulations, which is why we prioritize verifying their credentials before engaging in any partnerships.

Checking Certifications and Compliance

Manufacturers near me may have different certifications depending on their specialization, so it's essential to research what specific certifications are relevant to your product. This could include ISO certifications, FDA approvals, or industry-specific standards. By ensuring that potential manufacturers have the necessary qualifications, you can be confident in their ability to meet your production needs while maintaining quality standards.

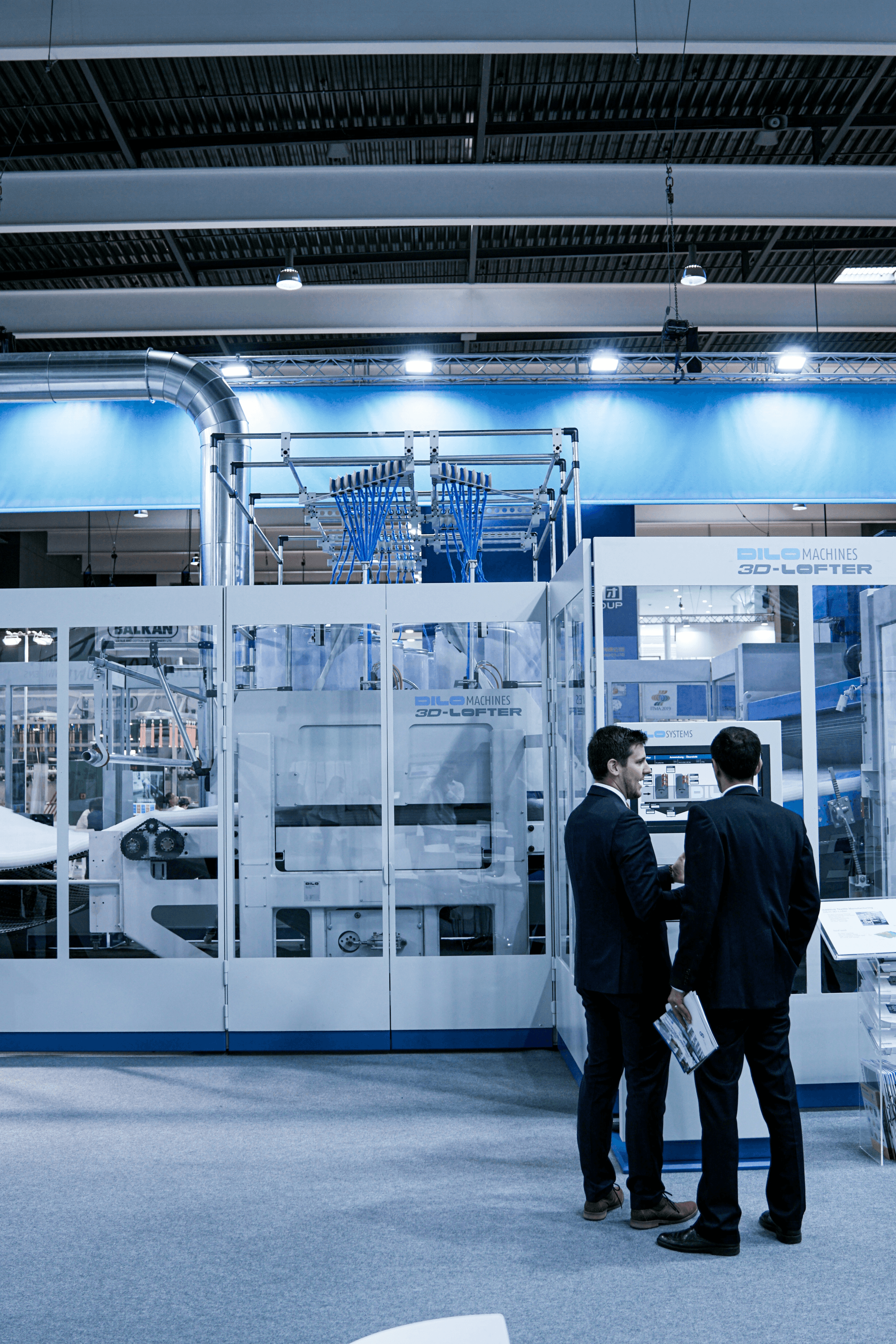

Assessing Production Facilities

Before finalizing any agreements, it's important to assess the production facilities of potential manufacturers. This involves visiting their factories or conducting virtual tours to evaluate their capabilities and infrastructure. At SSOURCING INC., we assist our clients in planning these visits to ensure that they have a comprehensive understanding of the manufacturer's production environment and capacity.

Confirming Quality Control Measures

Quality control is a critical aspect of manufacturing, especially when it comes to small business ventures or new product launches. It's essential to confirm that the manufacturer has robust quality control measures in place to uphold your product specifications and standards. By thoroughly reviewing these measures, you can mitigate potential risks and maintain consistency in your product's quality.

As you embark on your journey of finding manufacturers for your product, remember that thorough verification of credentials is key to establishing a successful partnership with a manufacturing supplier.

Stay tuned for more tips on how SSOURCING INC. can help you navigate the process of identifying the right manufacturer for your business needs!

Requesting for Quotations

Once you have identified potential manufacturers for your product, it's time to request for quotations. Sending detailed requests to each manufacturer will help you gather accurate pricing and terms for comparison. This step is crucial in finding the best manufacturing supplier that suits your business needs and budget.

Sending Detailed Requests

When sending out requests for quotations, be sure to provide a comprehensive outline of your product specifications, including materials, dimensions, and any specific requirements. This will help manufacturers near you understand the scope of the project and provide accurate pricing. Clearly outlining your expectations will also ensure that you receive relevant and detailed quotations.

Comparing Pricing and Terms

After receiving quotations from different manufacturers, take the time to compare pricing and terms offered by each. Look beyond just the cost and consider factors such as production lead times, payment terms, and quality guarantees. This comparison will help you make an informed decision when selecting a manufacturing supplier that aligns with your business goals.

Negotiating for Better Deals

Negotiating with potential manufacturers can lead to better deals that benefit both parties involved. Use the information gathered from comparing quotations to negotiate favorable terms such as volume discounts or extended payment schedules. Building a good relationship during this stage can set the foundation for a successful partnership with SSOURCING INC.

By following these steps in requesting for quotations from potential manufacturers near you, you can effectively evaluate their offerings and negotiate favorable deals that meet your small business needs while setting the foundation for successful production with SSOURCING INC.

Visiting Manufacturer Facilities

After narrowing down potential manufacturers for your product, the next crucial step is to plan factory visits. This allows you to personally assess their capabilities and ensure they meet your quality standards. When planning these visits, consider factors such as location, production capacity, and their ability to meet your specific product requirements.

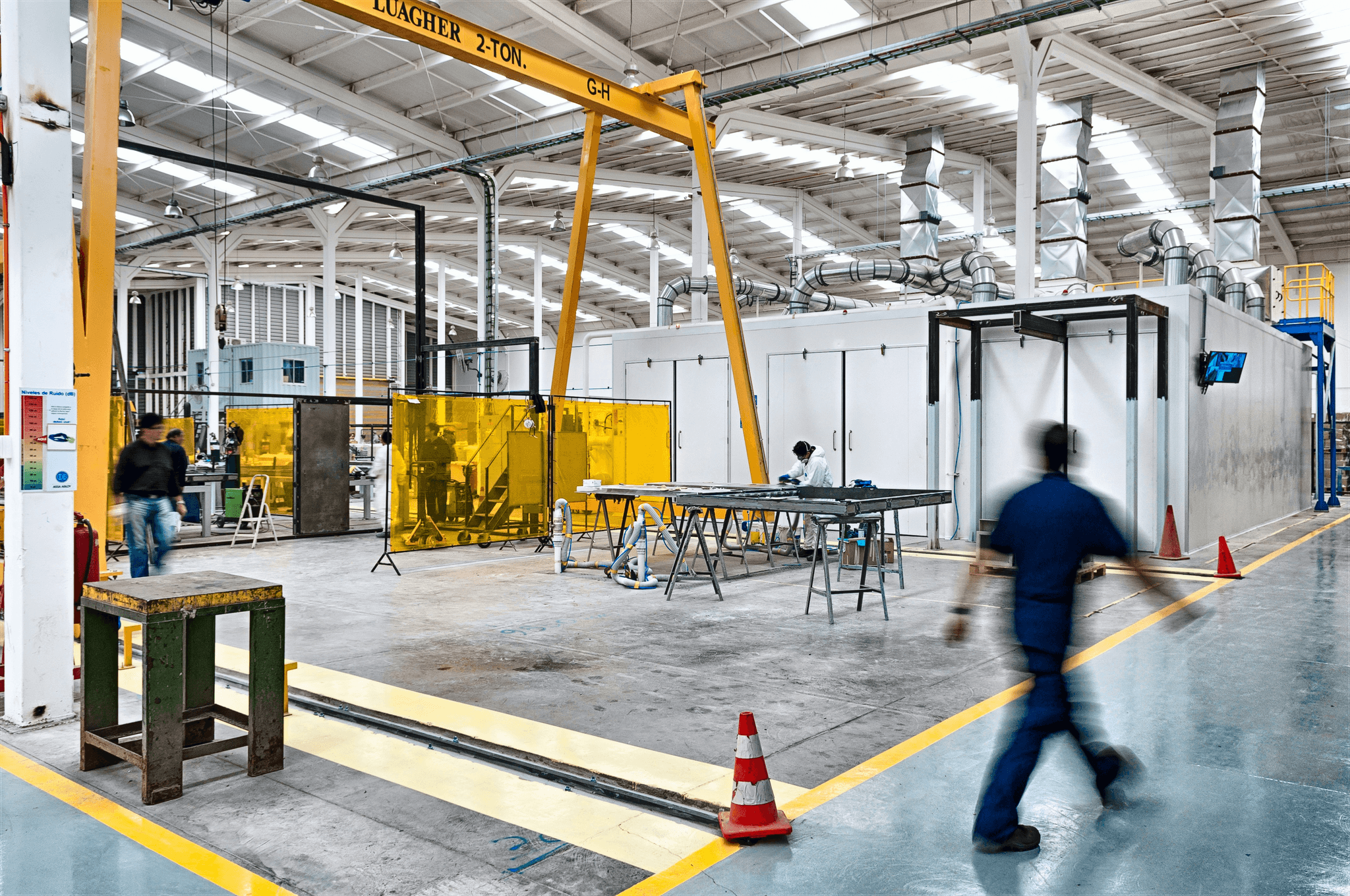

Planning Factory Visits

When looking for manufacturers near you, it's important to schedule factory visits to get a firsthand look at their operations. This can help you gauge their professionalism, production efficiency, and overall suitability for your business needs. By visiting manufacturing suppliers in person, you can gain valuable insights that may not be apparent through online research alone.

Inspecting Production Lines

During your factory visits, take the time to inspect the production lines in detail. Look for signs of quality control measures, adherence to safety standards, and overall cleanliness of the facilities. This will give you a better understanding of how your product will be manufactured and whether the manufacturer can meet your specifications.

Meeting with Management Team

In addition to inspecting the production lines, it's essential to meet with the management team of each potential manufacturer. This allows you to discuss your product requirements in detail, address any concerns or questions you may have, and gain a sense of their commitment to meeting your needs. Building a good rapport with the management team is crucial in establishing a successful partnership.

By following these steps when visiting manufacturer facilities, SSOURCING INC. ensures that every potential partner meets our stringent quality standards and aligns with our business goals.

Making the Final Decision

After carefully evaluating the pros and cons of each potential manufacturer, it is crucial to make a well-informed decision. Consider factors such as production capabilities, quality standards, pricing, and lead times when weighing your options. Look for manufacturers near you or explore business to business ideas that align with your small business needs. This decision will set the foundation for a successful partnership with manufacturing suppliers.

Weighing the Pros and Cons

When considering different manufacturing options, take into account the benefits and drawbacks of each potential partner. Look for how to find manufacturers for your product that meet your specific requirements while also offering competitive pricing and reliable production volume. It's important to weigh these factors against each other to make an informed decision that aligns with your business ideas and goals.

Finalizing Contracts and Agreements

Once you have selected a manufacturer that meets all of your criteria, it's time to finalize contracts and agreements. Ensure that all terms are clearly outlined, including product specifications, quality standards, pricing, lead times, and payment terms. This step is crucial in establishing a mutually beneficial partnership with SSOURCING INC., setting the stage for successful production.

Building a Lasting Partnership

Building a lasting partnership with your chosen manufacturer involves open communication, mutual respect, and a commitment to quality and consistency. Collaborate closely with the manufacturer to ensure that all aspects of production align with your small business needs and goals. By fostering a strong relationship from the start, you can establish a solid foundation for future growth and success.

Conclusion

Now that you have gone through the process of identifying your product needs, researching potential manufacturers, and evaluating their capabilities, it's time to make the final decision. Choosing the right manufacturer for your product is crucial to the success of your business. It's important to ensure that the manufacturer you select can meet your product specifications and quality standards while offering competitive pricing and terms.

Choosing the Right Manufacturer for Your Product

When looking for manufacturers near you or overseas, it's essential to consider their specialization, customer feedback, and credentials. By carefully analyzing these factors, you can make an informed decision about which manufacturing supplier is the best fit for your business. SSOURCING INC. can assist you in finding the right manufacturer that aligns with your business ideas and small business goals.

Ensuring Quality and Consistency

Quality control measures are vital in maintaining consistency in production. The chosen manufacturer should have certifications, compliance with industry standards, and well-equipped production facilities to ensure high-quality output. With SSOURCING INC., you can be confident that these aspects are thoroughly verified before finalizing contracts and agreements.

Setting the Foundation for Successful Production with SSOURCING INC.

Starting a business can be challenging, but with a reliable manufacturing partner like SSOURCING INC., you can set a strong foundation for successful production. Our team will assist you in negotiating better deals, planning factory visits, and building a lasting partnership with the selected manufacturer to support your good starter businesses' growth.

With careful consideration and thorough research, finding manufacturers for your product doesn't have to be daunting. By following these steps and partnering with SSOURCING INC., you can confidently navigate through the process of selecting a manufacturing supplier that meets all of your business-to-business ideas' requirements while setting up a successful production venture.