Introduction

In today's rapidly evolving business landscape, the impact of smart manufacturing solutions cannot be overstated. As technology continues to revolutionize the industry, companies are increasingly turning to advanced manufacturing solutions to stay ahead of the competition and maximize profit. At SSOURCING INC., we understand the pivotal role that technology plays in driving efficiency and profitability for our clients.

The Impact of Smart Manufacturing Solutions

Smart manufacturing solutions encompass a wide range of technologies and processes designed to optimize production and minimize waste. From automation and robotics to data analytics and predictive maintenance, these solutions are reshaping the way companies operate, allowing them to achieve higher levels of productivity and cost savings.

The Role of Technology in Maximizing Profit

Technology is no longer just a tool for improving operational efficiency; it has become a strategic asset for maximizing profit. By leveraging cutting-edge manufacturing solutions, companies can streamline their processes, reduce downtime, and make informed decisions based on real-time data, ultimately leading to improved bottom-line results.

Key Benefits of Adopting Manufacturing Solutions

The benefits of adopting smart manufacturing solutions are multifaceted. Not only do they drive efficiency and cost reduction, but they also enable companies to enhance quality control, improve supply chain management, and empower their workforce with safer and more efficient tools. At SSOURCING INC., we are committed to helping our clients unlock these key benefits through tailored manufacturing solutions that align with their unique business goals.

The Importance of Efficiency

In today's competitive manufacturing landscape, efficiency is the key to staying ahead of the game. By implementing smart manufacturing solutions, SSOURCING INC. can streamline its production processes, optimize resource utilization, and minimize waste. This not only saves time and money but also ensures that every step in the manufacturing chain adds value to the final product.

Streamlining Processes with Smart Manufacturing Solutions

Smart manufacturing solutions enable SSOURCING INC. to automate repetitive tasks, eliminate bottlenecks, and reduce lead times. By integrating technologies such as IoT sensors and real-time monitoring systems, the company can gain valuable insights into its production line, identify inefficiencies, and make data-driven decisions to improve overall workflow. This results in a more agile and responsive manufacturing process that adapts to changing market demands.

Increasing Productivity with Advanced Technology

With advanced technology at its disposal, SSOURCING INC. can boost productivity across its operations. From robotics and AI-powered machinery to advanced analytics tools, these innovations enable the workforce to focus on high-value tasks while machines handle routine activities with precision and speed. This not only accelerates production but also reduces human error, resulting in higher output quality.

Enhancing Quality Control for Better Profit Margins

By integrating smart manufacturing solutions into its quality control processes, SSOURCING INC. can ensure that every product meets stringent standards before reaching the market. Through automated inspection systems and real-time data analysis, the company can detect defects early on, rectify issues promptly, and ultimately minimize waste while maximizing profit margins.

By embracing efficiency through smart manufacturing solutions like automation and advanced technology integration, SSOURCING INC. is poised to revolutionize its operations for maximum profitability while maintaining top-notch quality control standards.

Cost Reduction Strategies

In today's competitive market, cost reduction is essential for maintaining profitability. Implementing lean manufacturing principles can help SSOURCING INC. optimize production processes and minimize waste, ultimately leading to significant cost savings. By eliminating non-value adding activities and streamlining operations, our company can achieve higher efficiency and reduce unnecessary expenses.

Implementing Lean Manufacturing Principles

Lean manufacturing involves identifying and eliminating waste in all forms, including overproduction, waiting time, transportation, extra processing, excess inventory, motion, and defects. By implementing lean principles, SSOURCING INC. can improve productivity and reduce costs by focusing on value-adding activities while eliminating non-essential processes that do not contribute to the final product.

Utilizing Predictive Maintenance for Cost Savings

Predictive maintenance uses advanced technology to predict when equipment failure is likely to occur based on data analysis of historical patterns. By adopting predictive maintenance solutions, SSOURCING INC. can avoid unexpected downtime and costly repairs by proactively addressing potential issues before they escalate into major problems.

Reducing Downtime with Smart Manufacturing Solutions

Downtime in production can be a significant source of cost for manufacturers due to lost productivity and potential rush orders to make up for lost time. Smart manufacturing solutions such as real-time monitoring and predictive analytics can help SSOURCING INC. minimize downtime by identifying potential issues before they cause disruptions in the production process.

By implementing these cost reduction strategies through lean principles, predictive maintenance, and smart manufacturing solutions at SSOURCING INC., we can enhance our operational efficiency while minimizing unnecessary expenses to maximize profitability in the competitive manufacturing landscape.

Data Analytics for Decision Making

In today's competitive market, leveraging big data for operational insights is crucial for staying ahead. By utilizing advanced manufacturing solutions, SSOURCING INC. can gather and analyze vast amounts of data to gain valuable insights into production processes, equipment performance, and resource utilization. This allows for informed decision-making that can drive efficiency and maximize profitability.

Leveraging Big Data for Operational Insights

By harnessing the power of big data, SSOURCING INC. can gain a comprehensive understanding of their manufacturing operations. This includes real-time monitoring of machine performance, predictive maintenance scheduling, and identifying areas for process optimization. With the ability to analyze historical data trends, the company can make proactive decisions to improve productivity and reduce operational costs.

Improving Supply Chain Management with Analytics

Integrating analytics into supply chain management enables SSOURCING INC. to optimize inventory levels, minimize lead times, and enhance supplier relationships. By analyzing demand patterns and production schedules, the company can ensure efficient material flow while reducing excess inventory holding costs. This strategic approach to supply chain management results in cost savings and improved customer satisfaction.

Maximizing Profit through Informed Decision Making

With data-driven insights at their disposal, SSOURCING INC. can make informed decisions that directly impact profitability. By identifying opportunities for process improvement or cost reduction through analytics, the company can proactively adjust production strategies to maximize profit margins. This proactive approach ensures that every decision is rooted in actionable intelligence derived from comprehensive data analysis.

Nowadays companies like SSOURCING INC are increasingly relying on advanced manufacturing solutions to leverage big data for operational insights, improving supply chain management with analytics and maximizing profit through informed decision making in order to stay competitive in the ever-evolving market landscape.

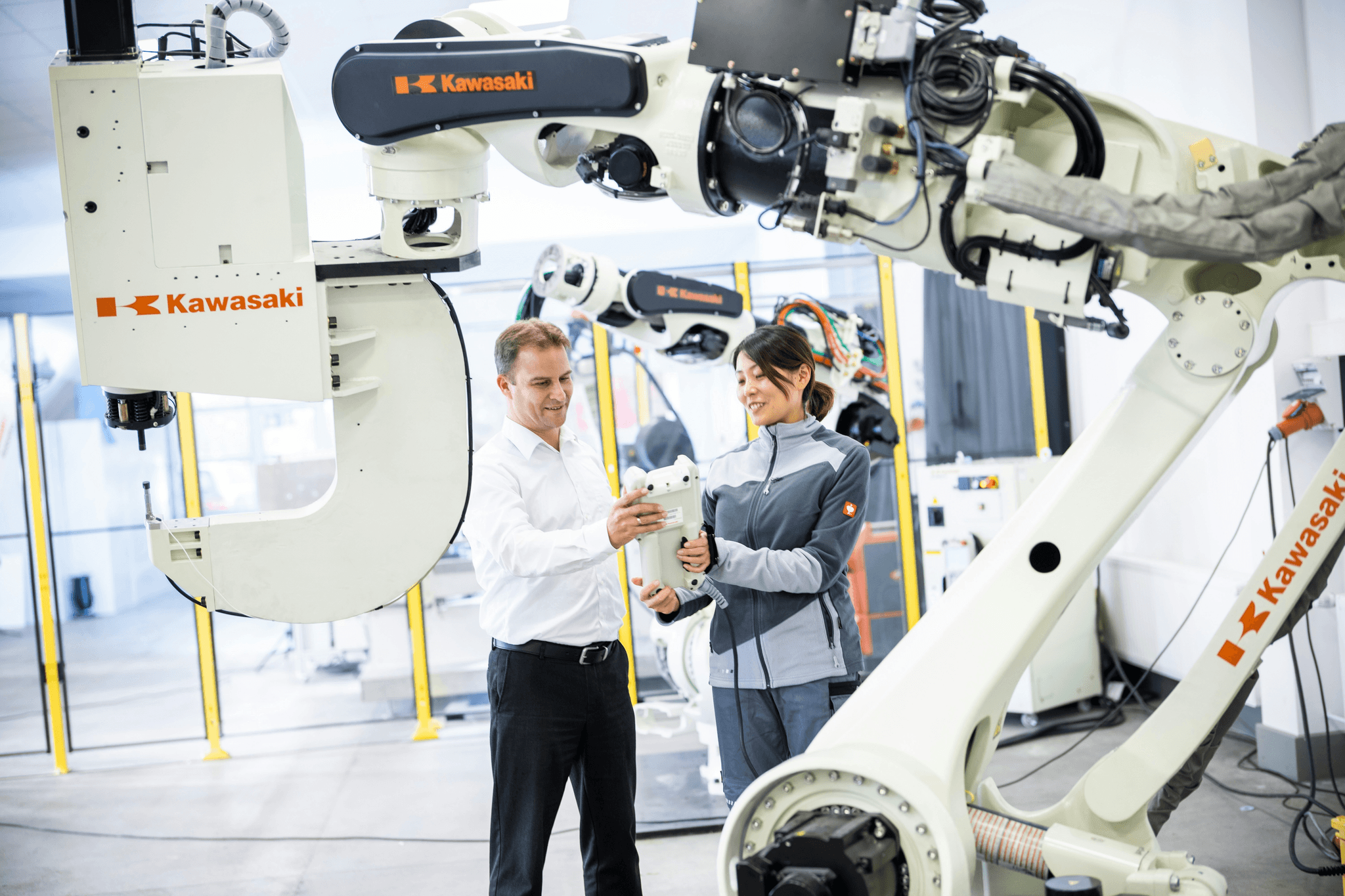

Human-Machine Collaboration

In today's fast-paced manufacturing landscape, the collaboration between human workers and advanced machines is crucial for success. By integrating smart manufacturing solutions, SSOURCING INC. can enhance worker safety and efficiency on the factory floor. With real-time monitoring and automated processes, workers can focus on high-value tasks while minimizing the risk of accidents.

Enhancing Worker Safety and Efficiency

Smart manufacturing solutions offer innovative tools that prioritize worker safety and optimize efficiency. With features such as predictive maintenance alerts and remote monitoring capabilities, SSOURCING INC. can ensure a secure working environment while maximizing productivity. By leveraging these technologies, our company can proactively address potential hazards and streamline operations for a more efficient workflow.

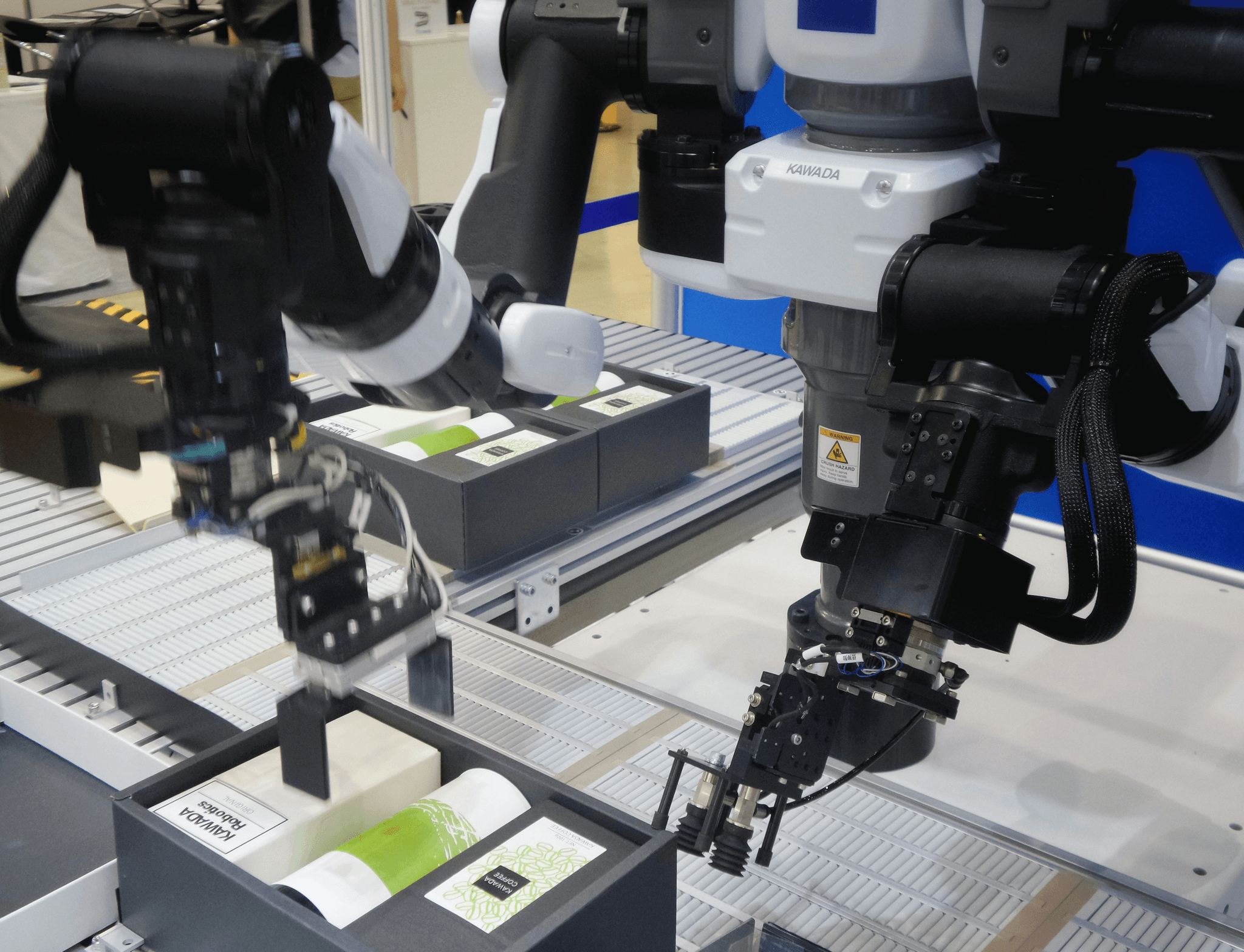

Harnessing the Power of Automation

Automation plays a significant role in modern manufacturing, allowing SSOURCING INC. to streamline processes and achieve higher levels of precision. By implementing robotic systems and automated assembly lines, our company can reduce manual labor requirements while maintaining consistent quality standards. This not only boosts overall productivity but also minimizes errors, leading to cost savings and improved profit margins.

Empowering the Workforce with Smart Manufacturing Solutions

The integration of smart manufacturing solutions empowers the workforce by providing them with advanced tools to excel in their roles. From augmented reality guidance systems to intelligent robotics, SSOURCING INC.'s employees can leverage cutting-edge technology to perform tasks with greater accuracy and efficiency. This not only enhances job satisfaction but also enables our workforce to contribute more effectively to the company's overall success.

Sustainable Manufacturing Practices

As the global focus on environmental sustainability grows, SSOURCING INC. recognizes the importance of incorporating environmental responsibility into our manufacturing operations. By implementing eco-friendly practices and utilizing green technology, we aim to minimize our ecological footprint while maximizing profitability.

Incorporating Environmental Responsibility into Operations

At SSOURCING INC., we are committed to integrating sustainable practices into our manufacturing processes. From reducing energy consumption and waste generation to promoting recycling and using renewable resources, we strive to minimize our impact on the environment. By embracing eco-friendly initiatives, we not only contribute to a healthier planet but also demonstrate our dedication to corporate social responsibility.

Meeting Regulatory Standards with Green Solutions

Adhering to regulatory standards is crucial for any manufacturing company, and at SSOURCING INC., we achieve this by leveraging green solutions. Our commitment to compliance with environmental regulations is evident in our use of sustainable materials, energy-efficient machinery, and environmentally friendly production methods. By meeting these standards, we ensure that our operations remain in line with industry requirements while promoting a cleaner, greener future.

Achieving Long-Term Profitability through Sustainable Practices

Incorporating sustainable practices into our manufacturing operations not only benefits the environment but also contributes to long-term profitability for SSOURCING INC. By reducing waste and minimizing resource consumption, we lower operational costs and increase efficiency. Additionally, as consumers increasingly prioritize eco-friendly products, our commitment to sustainability positions us as a responsible and forward-thinking brand in the market.

Conclusion

In conclusion, embracing smart manufacturing solutions is essential for gaining a competitive advantage in today's market. By leveraging advanced technology and data analytics, SSOURCING INC. can optimize operations and maximize profitability. As we look ahead, future trends in manufacturing solutions will continue to revolutionize the industry, unlocking even greater profit potential with smart technology.

Embracing Smart Manufacturing for Competitive Advantage

With the increasing complexity of global supply chains and consumer demands, it's crucial for companies like SSOURCING INC. to embrace smart manufacturing solutions to stay ahead of the competition. By integrating innovative technologies and sustainable practices into operations, businesses can enhance efficiency, reduce costs, and ultimately drive greater profitability.

A Look Ahead: Future Trends in Manufacturing Solutions

As technology continues to evolve at a rapid pace, the future of manufacturing solutions holds exciting possibilities for SSOURCING INC. From the rise of artificial intelligence and machine learning to advancements in robotics and 3D printing, staying informed about emerging trends will be key to maintaining a competitive edge in the industry.

Unlocking Profit Potential with Smart Technology

The potential for unlocking profit through smart technology is immense. By harnessing the power of automation, data analytics, and sustainable practices, companies can drive operational excellence while meeting evolving consumer expectations. SSOURCING INC. stands poised to capitalize on these opportunities and lead the way in maximizing profitability through innovative manufacturing solutions.