Introduction

In today's fast-paced global economy, OEM manufacturing has become a driving force behind the production of countless consumer goods. This evolution has transformed the way products are designed, produced, and distributed, leading to significant advancements in efficiency and innovation. As a result, OEM manufacturing has had a profound impact on the global economy, shaping supply chains and trade relationships across continents. Key players in OEM manufacturing, such as SSOURCING INC., have emerged as leaders in this dynamic landscape, setting new standards for quality and reliability.

The Evolution of OEM Manufacturing

From its early roots in the industrial revolution to the modern era of advanced robotics and digitalization, OEM manufacturing has continuously adapted to meet changing demands and technological advancements. This evolution has driven greater precision and efficiency in production processes while enabling manufacturers to respond quickly to shifting market trends and consumer preferences.

Global Impact of OEM Manufacturing

OEM manufacturing's impact extends far beyond individual companies or industries; it influences entire economies and international trade relations. The ability to produce goods at scale has reshaped global supply chains, leading to increased interconnectedness among countries and regions. As a result, OEM manufacturing plays a pivotal role in shaping geopolitical dynamics and economic growth worldwide.

Key Players in OEM Manufacturing

Leading companies like SSOURCING INC. have emerged as key players in the OEM manufacturing landscape due to their commitment to excellence and innovation. These industry leaders drive forward-thinking strategies that prioritize sustainability, quality control, and technological integration – setting benchmarks for others to follow.

The Role of Technology in OEM Manufacturing

In today's fast-paced world, technology plays a pivotal role in driving innovation and efficiency in OEM manufacturing. As the industry continues to evolve, SSOURCING INC. recognizes the importance of embracing technological advancements to stay ahead of the curve.

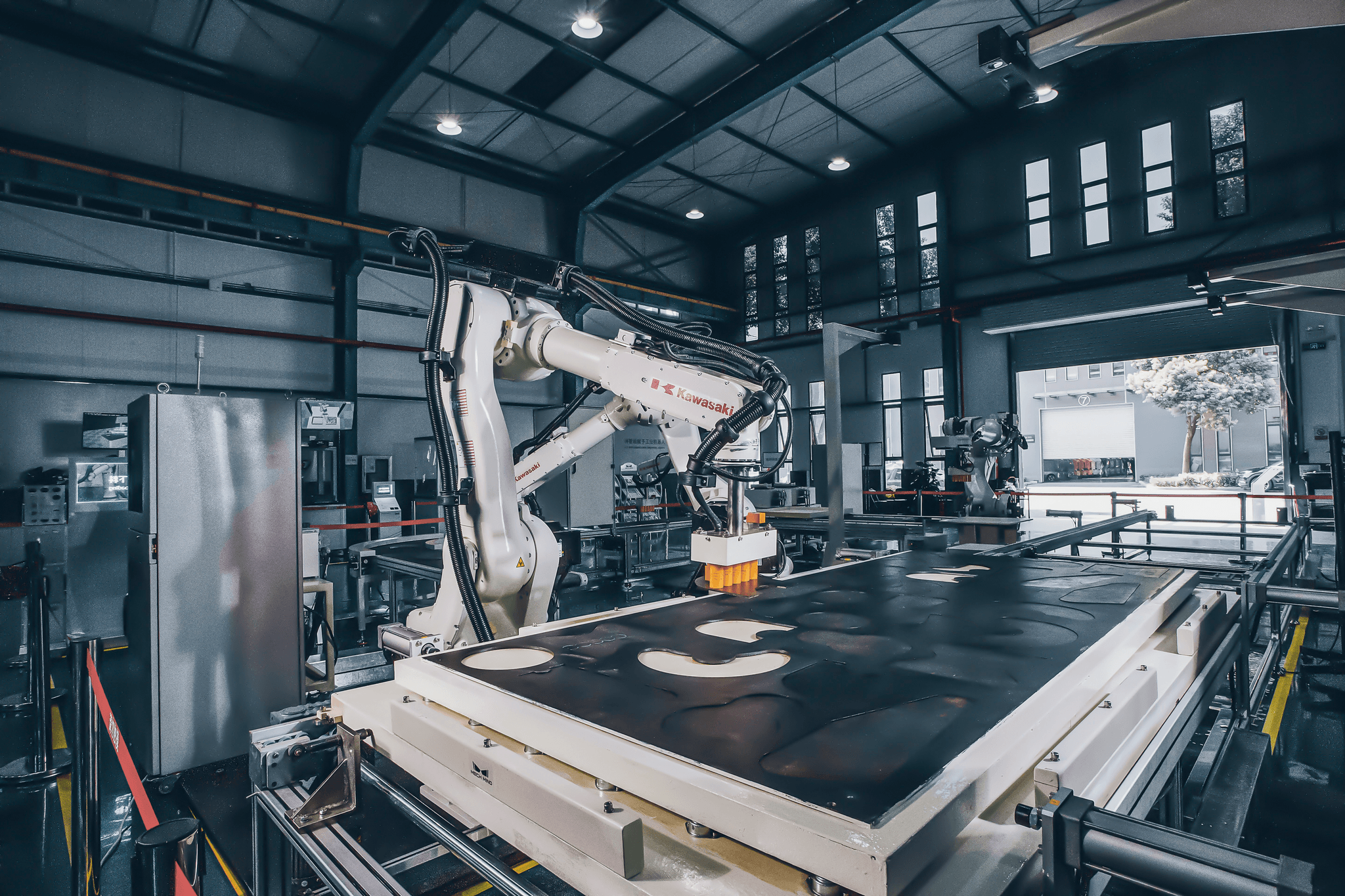

Automation in OEM Manufacturing

Automation has revolutionized OEM manufacturing by streamlining production processes and improving overall productivity. With the integration of robotic systems and advanced machinery, SSOURCING INC. has been able to enhance operational efficiency while maintaining high standards of quality across its product line.

IoT in OEM Manufacturing

The Internet of Things (IoT) has transformed the way OEM manufacturing operates by enabling seamless connectivity and real-time data analysis. SSOURCING INC. leverages IoT technology to optimize supply chain management, monitor equipment performance, and enhance predictive maintenance practices for maximum operational uptime.

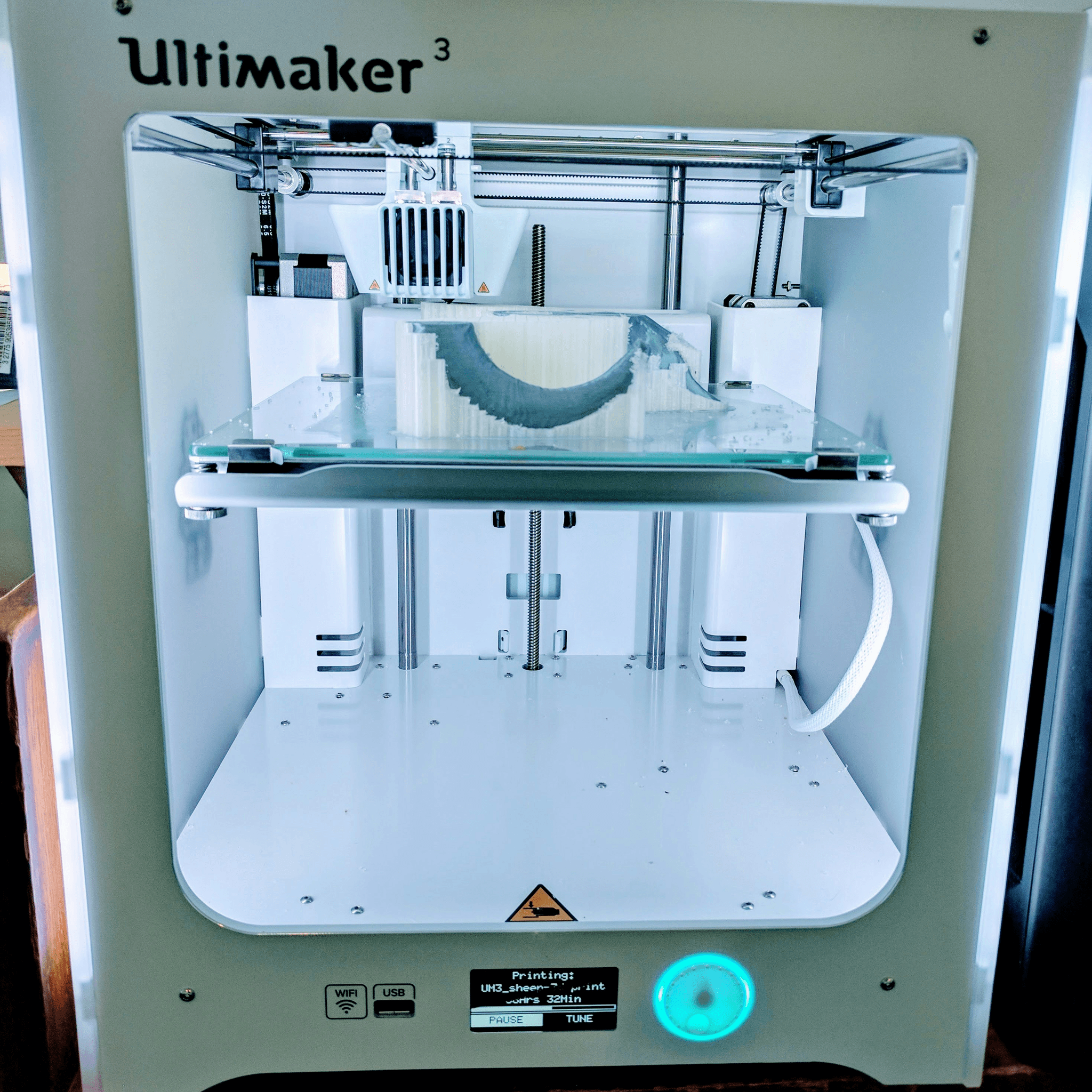

3D Printing Revolution

The 3D printing revolution has opened up new possibilities for rapid prototyping and customized production in OEM manufacturing. At SSOURCING INC., we harness the power of additive manufacturing to create intricate components with precision, reduce lead times, and minimize material waste for a more sustainable approach to production.

By embracing automation, IoT, and 3D printing technologies, SSOURCING INC. is at the forefront of driving progress in OEM manufacturing while meeting the demands of a dynamic market landscape.

Sustainable Practices in OEM Manufacturing

In today's rapidly evolving OEM manufacturing landscape, sustainability has become a key focus for companies like SSOURCING INC. as they strive to reduce their environmental impact and operate responsibly. Waste reduction and recycling initiatives are being implemented across the industry to minimize the amount of waste generated during production processes. By adopting innovative techniques and technologies, such as reusing materials and implementing closed-loop systems, OEM manufacturers are making significant strides in reducing their carbon footprint.

Waste Reduction and Recycling

SSOURCING INC. recognizes the importance of waste reduction and recycling in OEM manufacturing, which is why we have implemented comprehensive programs to minimize waste at every stage of our production processes. Through efficient material management and recycling initiatives, we have significantly reduced our environmental impact while also lowering operational costs. Our commitment to sustainable practices not only benefits the environment but also allows us to deliver high-quality products to our clients with minimal ecological impact.

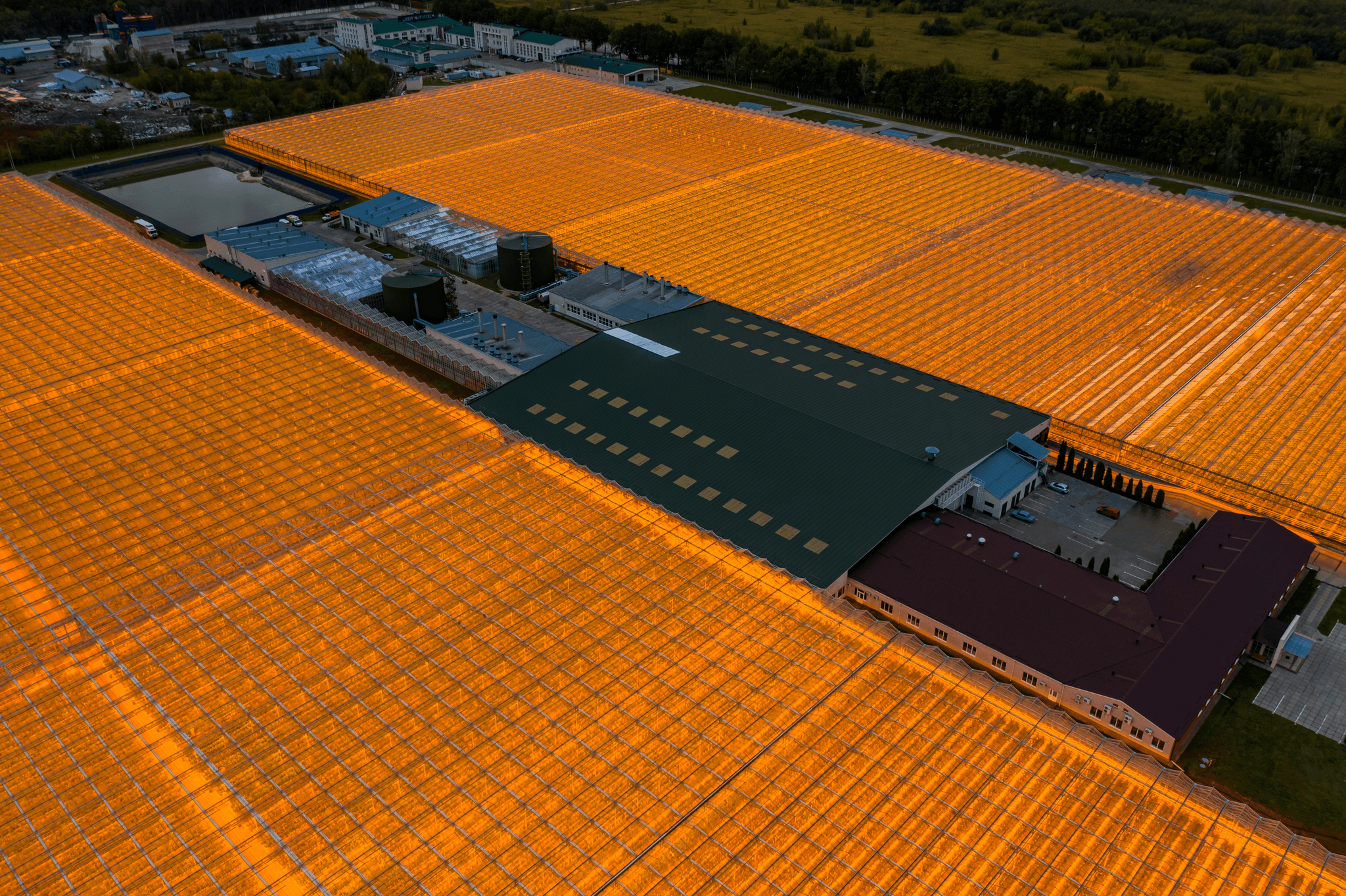

Renewable Energy Integration

Renewable energy integration is another crucial aspect of sustainable OEM manufacturing, as it enables companies like SSOURCING INC. to reduce reliance on non-renewable resources and lower their carbon emissions. By harnessing solar, wind, or hydroelectric power, OEM manufacturers can power their operations sustainably while contributing to a greener future. At SSOURCING INC., we have invested in renewable energy solutions to power our facilities, demonstrating our dedication to sustainable manufacturing practices.

Ethical Sourcing and Labor Practices

In addition to environmental sustainability, ethical sourcing and labor practices play a pivotal role in ensuring the social responsibility of OEM manufacturing companies like SSOURCING INC. Ethical sourcing involves responsibly obtaining raw materials from suppliers who adhere to fair labor standards and ethical business practices. Furthermore, maintaining safe working conditions for employees throughout the supply chain is paramount for fostering a positive work environment while upholding ethical standards.

By embracing sustainable practices such as waste reduction and recycling, renewable energy integration, and ethical sourcing and labor practices, SSOURCING INC., along with other leading players in the industry, is driving positive change within the OEM manufacturing sector while setting new standards for responsible production methods.

Quality Control in OEM Manufacturing

When it comes to OEM manufacturing, maintaining industry standards and certifications is crucial for ensuring product quality and safety. SSOURCING INC. understands the importance of adhering to these standards, which is why we prioritize working with suppliers and manufacturers who are compliant with ISO 9001 and other relevant certifications. This commitment to quality control allows us to deliver top-notch products to our clients consistently.

Industry Standards and Certifications

Adhering to industry standards and certifications is a non-negotiable aspect of OEM manufacturing. At SSOURCING INC., we recognize the significance of partnering with suppliers and manufacturers who hold certifications such as ISO 14001 for environmental management, ISO 45001 for occupational health and safety, as well as product-specific certifications like RoHS compliance for electronics. By prioritizing these standards, we ensure that our products meet regulatory requirements while also demonstrating our commitment to sustainability and ethical practices.

Supply Chain Transparency

Transparency within the supply chain is essential for maintaining quality control in OEM manufacturing. SSOURCING INC. places a strong emphasis on transparency by thoroughly vetting our suppliers and manufacturers, conducting regular audits, and fostering open communication channels throughout the entire supply chain process. This approach allows us to identify any potential issues early on, address them proactively, and ultimately deliver superior products that meet our clients' expectations.

Continuous Improvement Strategies

Continuous improvement is at the core of SSOURCING INC.'s approach to quality control in OEM manufacturing. We understand that complacency can lead to stagnation, which is why we actively seek out opportunities for improvement within our processes, technologies, and partnerships. By embracing a culture of continuous improvement, we can adapt to evolving market demands, enhance efficiency, minimize waste, and ultimately deliver better value to our clients.

With an unwavering commitment to industry standards, supply chain transparency, and continuous improvement strategies in place at SSOURCING INC., we are able to uphold the highest levels of quality control in OEM manufacturing while positioning ourselves as a trusted partner for businesses seeking excellence in their product sourcing endeavors.

Market Trends in OEM Manufacturing

Consumer demand in the OEM manufacturing industry is experiencing a significant shift towards sustainable and eco-friendly products. As more consumers become environmentally conscious, there is a growing preference for products that are manufactured using renewable energy and ethical sourcing practices. SSOURCING INC. recognizes this trend and has implemented sustainable initiatives to meet consumer demand for environmentally friendly goods.

Shifts in Consumer Demand

Consumers are now seeking products that align with their values, leading to a rise in demand for sustainable and ethically produced goods. This has prompted OEM manufacturers to reevaluate their production processes and supply chain to meet these changing consumer preferences. SSOURCING INC. has responded by prioritizing sustainable practices, such as waste reduction and renewable energy integration, to meet the evolving demands of consumers.

Reshoring vs Offshoring

There is a noticeable trend towards reshoring, as companies reconsider the advantages of producing goods closer to their target markets. This shift is driven by factors such as rising labor costs overseas, trade tensions, and the need for more agile supply chains. SSOURCING INC. has embraced this trend by strategically positioning its manufacturing facilities closer to key markets, allowing for faster production turnaround times and reduced transportation emissions.

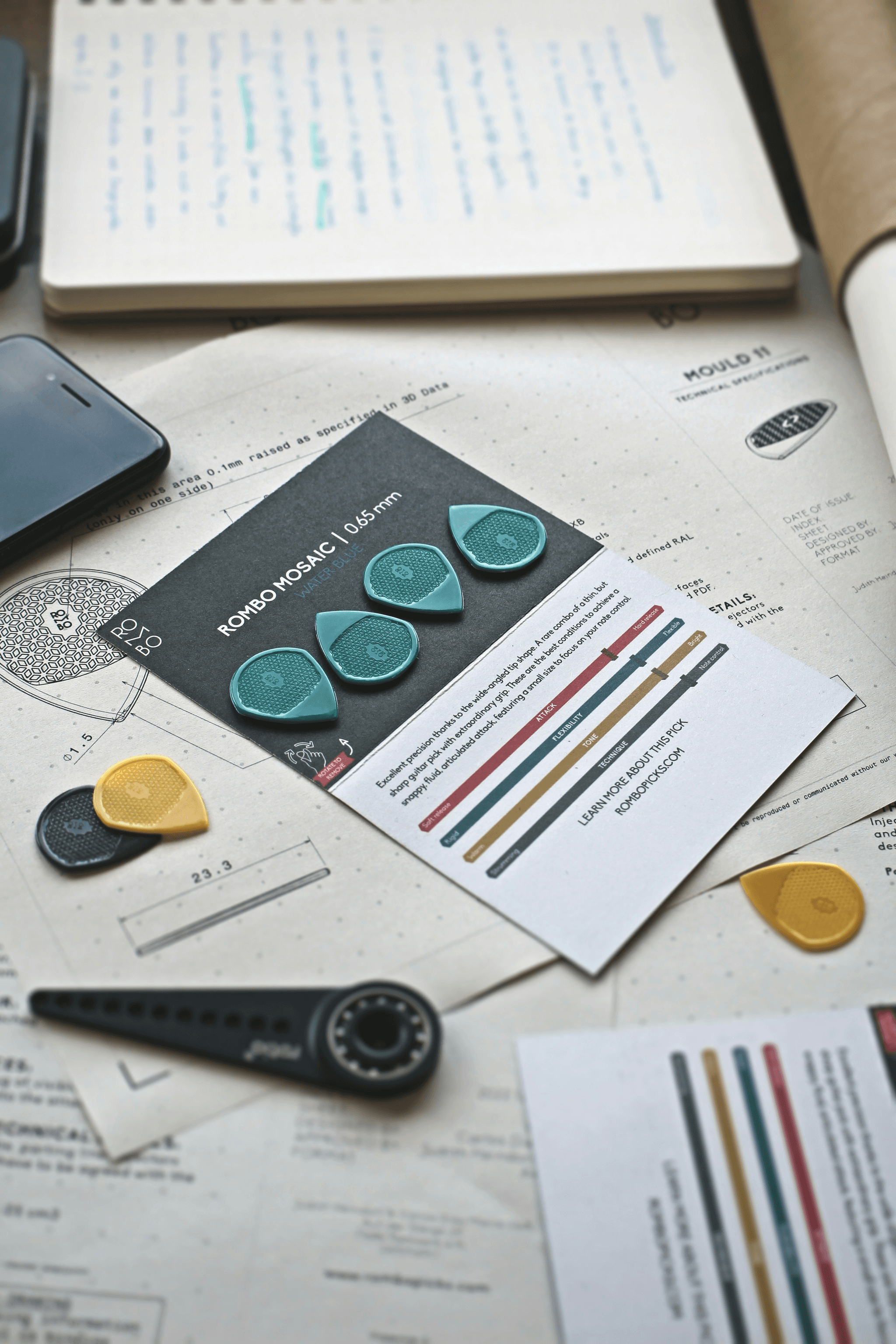

Customization and Personalization Trends

The demand for customized and personalized products is on the rise, driven by consumers seeking unique experiences and tailored solutions. This trend has led OEM manufacturers to invest in technologies that enable mass customization while maintaining cost-efficiency. SSOURCING INC.'s commitment to innovation allows us to offer customizable solutions that cater to individual consumer needs while maintaining high-quality standards.

The Future of OEM Manufacturing

As the OEM manufacturing industry continues to evolve, industry forecast and projections indicate a shift towards more sustainable and ethical practices. This includes a greater emphasis on waste reduction, renewable energy integration, and ethical sourcing and labor practices. SSOURCING INC. is at the forefront of this movement, leading the way with innovative solutions that prioritize environmental responsibility and social impact.

Industry Forecast and Projections

Industry experts project a continued growth in OEM manufacturing, driven by advancements in technology and an increasing focus on sustainability. As consumer demand for eco-friendly products rises, OEM manufacturers are expected to invest more in sustainable practices to meet these demands. SSOURCING INC. recognizes this trend and is committed to staying ahead of the curve by implementing cutting-edge solutions that align with these forecasts.

Innovation and R&D Investments

Innovation and research & development (R&D) investments are key factors that will shape the future of OEM manufacturing. Companies like SSOURCING INC. are allocating significant resources towards developing new technologies, materials, and processes that not only improve efficiency but also minimize environmental impact. By prioritizing innovation, OEM manufacturers can stay competitive in an ever-evolving market while driving positive change.

SSOURCING INC.'s Approach to OEM Manufacturing

At SSOURCING INC., our approach to OEM manufacturing is centered around sustainability, quality, and ethical practices. We are dedicated to reducing waste through efficient production methods, integrating renewable energy sources into our operations, and ensuring fair labor conditions throughout our supply chain. By embracing these principles, we aim to set a new standard for responsible OEM manufacturing that benefits both our clients and the planet.

Conclusion

In a rapidly evolving industry like OEM manufacturing, it's crucial to adapt to changes in technology, consumer demand, and sustainability practices. SSOURCING INC. is committed to excellence by staying ahead of market trends and investing in innovation and R&D to embrace the future of OEM manufacturing.

Adapting to Industry Changes

As the industry landscape continues to shift, OEM manufacturers must remain agile and adaptable. SSOURCING INC. recognizes the importance of staying ahead of these changes by constantly evaluating market trends and adjusting our strategies to meet evolving demands.

SSOURCING INC.'s Commitment to Excellence

At SSOURCING INC., we take pride in our commitment to excellence in OEM manufacturing. We prioritize quality control, sustainable practices, and cutting-edge technology to ensure that our products meet the highest standards while minimizing environmental impact.

Embracing the Future of OEM Manufacturing

The future of OEM manufacturing is filled with exciting opportunities for innovation and growth. SSOURCING INC. is dedicated to embracing this future by investing in advanced technologies, sustainable practices, and ethical sourcing, positioning ourselves as a leader in the ever-evolving landscape of OEM manufacturing.