Introduction

The world of marble manufacturing has seen a remarkable evolution in recent years, with the rise of Carrara marble manufacturers leading the charge. These manufacturers have been at the forefront of cutting-edge innovations in marble manufacturing, revolutionizing the industry with their forward-thinking approach. The impact of technology on marble production cannot be overstated, as it has transformed traditional methods and propelled the industry into a new era of efficiency and quality.

The Rise of Carrara Marble Manufacturers

The emergence of Carrara marble manufacturers has reshaped the landscape of the industry, bringing a fresh perspective and innovative techniques to the table. As demand for high-quality marble continues to soar, these manufacturers have risen to prominence by delivering exceptional products that meet the highest standards. SSOURCING INC. is proud to be among these trailblazers, pushing boundaries and setting new benchmarks for excellence in marble manufacturing.

Innovations in Marble Manufacturing

Innovations in marble manufacturing have been instrumental in enhancing both the quality and efficiency of production processes. From state-of-the-art machinery to advanced cutting and polishing techniques, manufacturers are constantly pushing the envelope to deliver superior products. At SSOURCING INC., we have embraced these innovations wholeheartedly, leveraging cutting-edge technology to elevate our craftsmanship and create truly exceptional marble products that stand out in the market.

The Impact of Technology on Marble Production

Technology has revolutionized every aspect of marble production, from extraction to finishing touches, leading to unparalleled precision and consistency in every piece. With advancements such as digital scanning and 3D modeling, manufacturers are able to achieve remarkable accuracy in veining and color matching. At SSOURCING INC., we recognize the transformative power of technology and continue to integrate it seamlessly into our processes, ensuring that our products exceed expectations at every turn.

The History of Marble Manufacturing

Marble has been synonymous with luxury and elegance for centuries, and its rich history in manufacturing dates back to ancient times. From the renowned marble supplier of Michelangelo to the timeless artistry of Calacatta marble, the legacy of this exquisite material continues to captivate designers and architects worldwide.

Michelangelo's Marble Supplier

The iconic sculptures created by Michelangelo wouldn't have been possible without the high-quality marble supplied by renowned quarries in Carrara, Italy. This pristine white marble, known for its fine grain and pure color, became synonymous with the Renaissance era and set the standard for excellence in marble manufacturing.

Timeless Artistry of Calacatta Marble

Calacatta marble, a rare and luxurious stone prized for its distinctive veining and luminous white background, has been revered for centuries as a symbol of opulence and sophistication. Its timeless beauty continues to inspire modern interior design projects, showcasing SSOURCING INC.'s commitment to sourcing only the finest materials for their clients.

Ancient Techniques vs Modern Methods

While ancient artisans relied on traditional hand tools and techniques to carve and sculpt marble, modern methods have revolutionized the manufacturing process. With advancements in technology and machinery, SSOURCING INC. has embraced cutting-edge tools that allow for precision cutting, polishing, and shaping of marble with unparalleled efficiency.

With a rich history steeped in tradition and artistry, marble manufacturing has evolved over time to meet the demands of contemporary design while preserving its timeless allure. As SSOURCING INC. continues to uphold these traditions while embracing innovation, they remain at the forefront of providing top-quality marble products for their discerning clientele.

Sustainable Practices in Marble Manufacturing

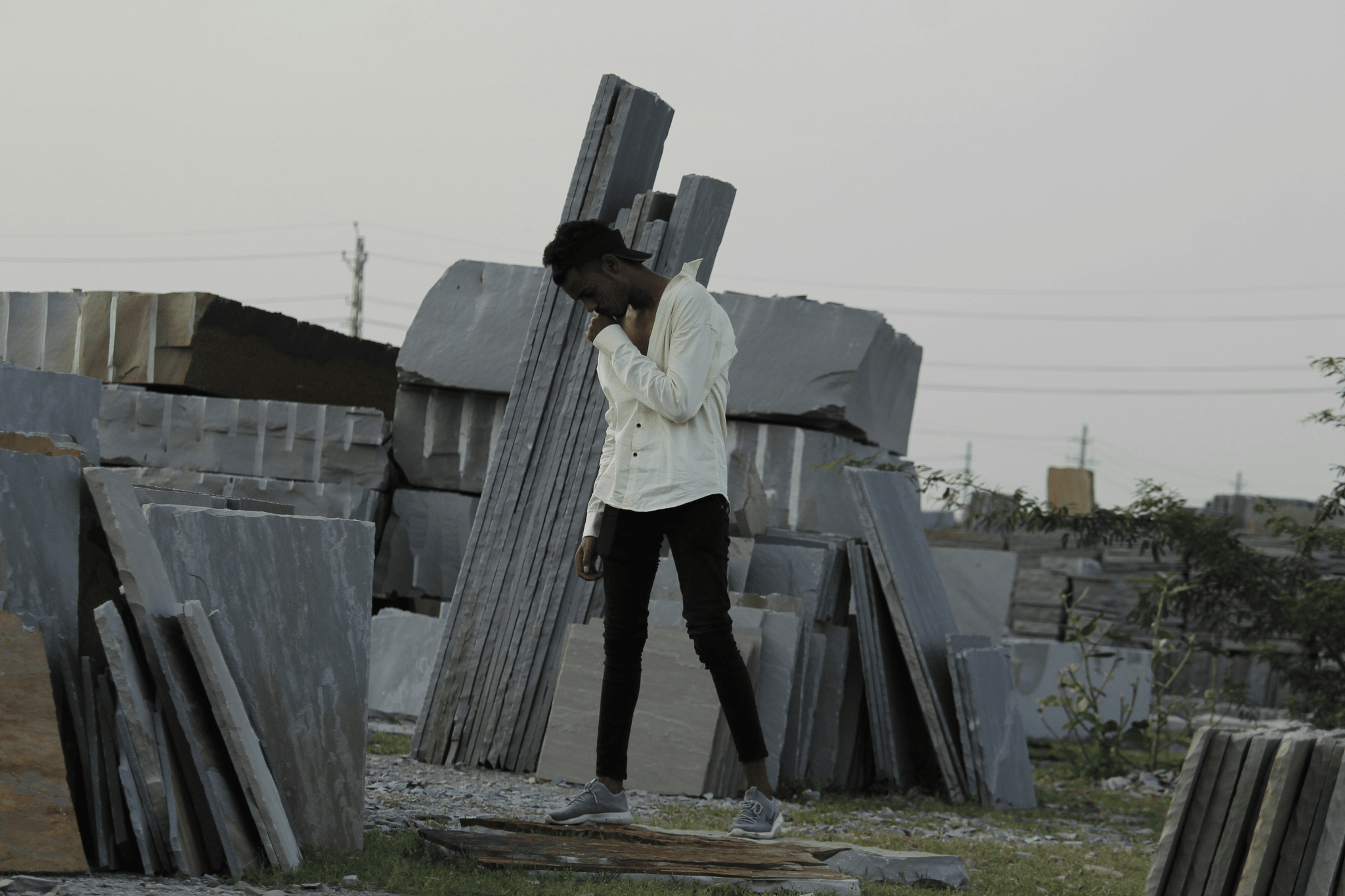

As the demand for ethically sourced materials grows, marble manufacturers are under increasing pressure to ensure that their sourcing practices are environmentally and socially responsible. SSOURCING INC. has set a shining example in this regard, by establishing partnerships with quarries that adhere to strict ethical standards, ensuring fair wages and safe working conditions for laborers.

Ethical Sourcing: A Case Study of SSOURCING INC.

SSOURCING INC. has made a conscious effort to prioritize ethical sourcing in their marble manufacturing process. By carefully selecting suppliers who adhere to fair labor practices and environmental regulations, they have been able to provide high-quality marble while also supporting sustainable and responsible business practices.

Environmental Impact of Marble Extraction

The extraction of marble can have a significant impact on the environment, as it often involves the clearing of natural habitats and the use of heavy machinery that emits harmful pollutants. However, SSOURCING INC. has taken steps to minimize their environmental footprint by investing in eco-friendly extraction methods and reforestation efforts in areas affected by quarrying.

Cutting-edge Recycling Techniques

In an effort to reduce waste and promote sustainability, SSOURCING INC. has implemented cutting-edge recycling techniques that allow them to repurpose scrap marble into new products or incorporate it into their manufacturing process. This not only minimizes waste but also adds an innovative touch to their product line, appealing to environmentally conscious consumers.

By prioritizing ethical sourcing, minimizing environmental impact, and embracing recycling techniques, SSOURCING INC. is leading the way in sustainable marble manufacturing practices while setting a positive example for the industry as a whole.

Quality Control in Marble Manufacturing

When it comes to marble manufacturing, ensuring consistency in veining and color is crucial for maintaining high-quality standards. Marble manufacturers like SSOURCING INC. utilize advanced technology to carefully monitor and control the veining and color of their marble products, guaranteeing uniformity and visual appeal in every piece. By implementing rigorous quality control measures, they are able to deliver premium marble materials that meet the expectations of designers, architects, and homeowners alike.

Ensuring Consistency in Veining and Color

SSOURCING INC. employs state-of-the-art imaging systems that analyze the natural patterns and hues of marble slabs, allowing for precise selection and matching during the production process. This meticulous attention to detail ensures that each batch of marble maintains a consistent appearance, making it easier for customers to visualize how the material will look in their spaces. By prioritizing consistency in veining and color, SSOURCING INC. sets itself apart as a reliable and reputable marble manufacturer that delivers top-notch products.

Precision Cutting and Polishing

In addition to maintaining uniform veining and color, precision cutting and polishing are essential aspects of quality control in marble manufacturing. SSOURCING INC.'s cutting-edge machinery utilizes advanced techniques to achieve flawless cuts and immaculate finishes on their marble products. This commitment to precision not only enhances the aesthetic appeal of the marble but also ensures that each piece meets exact specifications, providing customers with high-quality materials that elevate their interior design projects.

Industry Standards and Certifications

As a leading marble manufacturer, SSOURCING INC. adheres to industry standards and holds certifications that validate the quality of their products. By meeting stringent criteria set forth by regulatory bodies, they demonstrate their dedication to producing superior marble materials that meet or exceed industry benchmarks for durability, performance, and sustainability. These certifications serve as a testament to SSOURCING INC.'s commitment to excellence in every aspect of their manufacturing processes.

Marketing and Branding for Marble Manufacturers

Leveraging Social Media for Brand Exposure

In today's digital age, marble manufacturers like SSOURCING INC. are leveraging social media platforms to showcase their stunning marble products. With visually appealing content and engaging posts, they can reach a wider audience and connect with potential clients on platforms such as Instagram, Facebook, and Pinterest. By actively engaging with followers and sharing behind-the-scenes glimpses of their manufacturing process, marble manufacturers can build a strong online community and increase brand exposure.

Building a Strong Online Presence

Having a well-designed website is crucial for marble manufacturers to establish credibility and showcase their product range. A user-friendly website with high-quality images, detailed product descriptions, and customer testimonials can help build trust with potential buyers. Additionally, investing in search engine optimization (SEO) to ensure their website ranks high on search engine results pages is essential for driving organic traffic to their site.

Collaborating with Renowned Designers and Architects

Collaborating with renowned designers and architects can elevate the brand image of marble manufacturers. By partnering with industry influencers, they can gain exposure to new audiences while benefiting from the expertise of these professionals in creating stunning designs that highlight the beauty of their marble products.

This image features a screenshot of SSOURCING INC.'s Instagram page where they are showcasing their latest collection of marbles through visually appealing posts and engaging captions to captivate potential clients on social media platforms.

Conclusion

In conclusion, the future of marble manufacturing looks promising as technology continues to advance, allowing for more efficient and sustainable practices. With the rise of eco-friendly initiatives and ethical sourcing, companies like SSOURCING INC. are leading the way in setting new industry standards for responsible production.

The Future of Marble Manufacturing

The future of marble manufacturing lies in embracing cutting-edge technology and sustainable practices to minimize environmental impact. As demand for ethically sourced materials grows, marble manufacturers will need to adapt and innovate to meet these changing expectations. SSOURCING INC. is at the forefront of this movement, setting an example for others to follow.

Key Takeaways for Aspiring Marble Manufacturers

For aspiring marble manufacturers, it's crucial to prioritize ethical sourcing, quality control, and environmentally conscious practices from the outset. Building a strong online presence and leveraging social media can also help in reaching a wider audience and establishing brand recognition in a competitive market. By following in the footsteps of industry leaders like SSOURCING INC., newcomers can set themselves up for success.

The Enduring Legacy of Marble in Design

Despite advancements in technology and manufacturing processes, the timeless allure of marble remains unchanged. Its enduring legacy in design is a testament to its unparalleled beauty and versatility. As architects and designers continue to collaborate with marble manufacturers like SSOURCING INC., we can expect to see this elegant material continue to grace interiors and exteriors around the world.